Push the button!

In industrial automation systems, power continuity is fundamental. To ensure uninterrupted operation of machinery and production lines, switchgear must not only distribute energy but also guarantee reliable power control and protection. At TAKOM, we provide solutions based on MCC (Motor Control Center) switchgear – a key component of the electrical infrastructure in modern manufacturing facilities.

Unlike traditional switchgear, MCC systems are equipped with withdrawable modules. This means that in the event of a device failure, there’s no need to shut down the entire installation – only the faulty module needs to be replaced. This saves time, reduces production losses, and increases process safety.

We offer switchboards from EATON: xEnergy Elite and Rockwell Automation: CUBIC. See which solution is right for your project:

The xEnergy Elite Switchboard is an advanced MCC with withdrawable modules system for motor control and power distribution up to 6300A, designed for demanding industrial and commercial environments. Its main advantage lies in its high modularity and the ability to be individually configured for specific needs—up to 32 withdrawable units per section.

The switchboard is engineered to provide maximum protection against arc faults. The fully insulated busbars supplying the motor and feeder withdrawable units are classified as an arc fault-protected zone and offer IP4X protection, significantly enhancing operator safety and system reliability. xEnergy Elite also ensures energy efficiency, space-saving installation, and compliance with current safety standards, making it an ideal solution for modern and secure electrical installations.

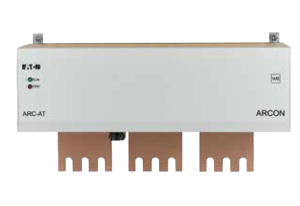

Eaton’s ARCON System is an active arc fault protection solution for low-voltage switchgear. It detects and extinguishes arc faults in less than 2 milliseconds, minimizing risk to personnel and equipment as well as damage and downtime.

Stacja MCC IEC CENTERLINE 2500 Low-Voltage wykorzystuje najnowszą technologię sterowania silnikami. Zastosowanie stacji IEC CENTERLINE 2500 pozwala osiągnąć światowe standardy, zintegrowaną architekturę sterowania oraz wysoki poziom bezpieczeństwa.

Cechy:

Rozdzielnice silnikowe IEC CENTERLINE 2500 ArcShield to rozdzielnice wyposażone w technologie pomagające jeszcze lepiej chronić personel i sprzęt w przypadku powstania łuku.

Cechy:

Technologia IntelliCENTER zwiększa inteligencję/możliwości rozdzielnicy dzięki wbudowanym prekonfigurowanym ekranom do monitoringu i konfiguracji rozdzielnicy i sieci. Pozwala zredukować czas instalacji korzystając z mechanizmu plug-and-play. Oferuje szybszy i zdalny dostęp do informacji o stanie napędów, diagnostykę systemu i predykcję usterek.

Cechy:

Oprogramowanie IntelliCENTER zapewnia najwyższą diagnostykę stacji MCC w czasie rzeczywistym. Wizualizacje poszczególnych jednostek stacji MCC pozwalają szybko odczytać ich aktualny stan.

Cechy:

Wondering if this solution is right for you?

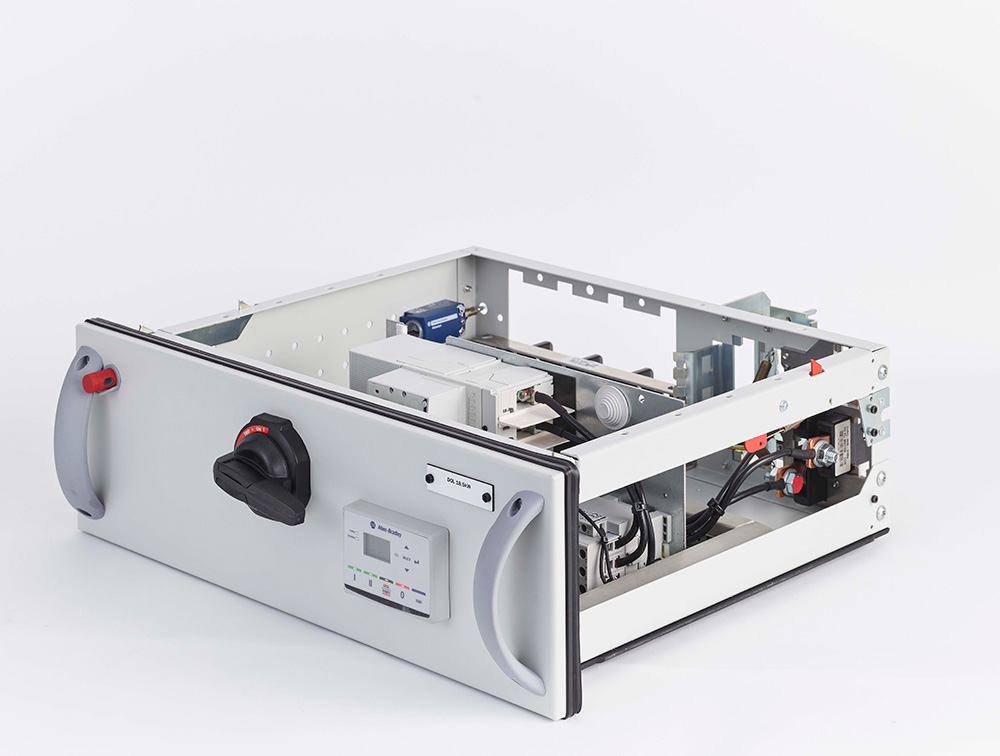

The MCC (Motor Control Center) system in Cubic switchboards is a modular solution for controlling and supplying power to electric motors up to 6300A. It is based on withdrawable drawers, allowing for easy replacement and expansion without shutting down the entire installation. The system offers high configuration flexibility, enabling the integration of equipment from various manufacturers and quick adaptation to changing needs—again, without requiring a complete shutdown. Thanks to internal separation Form 4 and compliance with the IEC 61439 standard, the system ensures a high level of safety for both operators and equipment.

The switchboards are resistant to short circuits, electric arcs, and are certified for quality. This makes the Cubic MCC system ideal for industrial, energy, and infrastructure applications—where reliability, operational continuity, safety, and flexible serviceability are critical. As a result, these switchboards reduce the risk of failures and minimize downtime, leading to increased operational efficiency and safety.

Stacja MCC IEC CENTERLINE 2500 Low-Voltage wykorzystuje najnowszą technologię sterowania silnikami. Zastosowanie stacji IEC CENTERLINE 2500 pozwala osiągnąć światowe standardy, zintegrowaną architekturę sterowania oraz wysoki poziom bezpieczeństwa.

Cechy:

Rozdzielnice silnikowe IEC CENTERLINE 2500 ArcShield to rozdzielnice wyposażone w technologie pomagające jeszcze lepiej chronić personel i sprzęt w przypadku powstania łuku.

Cechy:

Technologia IntelliCENTER zwiększa inteligencję/możliwości rozdzielnicy dzięki wbudowanym prekonfigurowanym ekranom do monitoringu i konfiguracji rozdzielnicy i sieci. Pozwala zredukować czas instalacji korzystając z mechanizmu plug-and-play. Oferuje szybszy i zdalny dostęp do informacji o stanie napędów, diagnostykę systemu i predykcję usterek.

Cechy:

Oprogramowanie IntelliCENTER zapewnia najwyższą diagnostykę stacji MCC w czasie rzeczywistym. Wizualizacje poszczególnych jednostek stacji MCC pozwalają szybko odczytać ich aktualny stan.

Cechy:

Your challenge – our solution. Let’s start with a short conversation.

Copy @ TAKOM Sp. z o.o. 2024 All rights reserved | Designed and Development by Pracownia Kresek